Couvreur Chevalier, spécialiste des membranes TPO blanches

Résidentiel et commercial

With an experienced team, we carry out on average more than 300 repairs per year. For quality work in Columbus , trust Couvreur Chevalier.

Nos services

We offer a wide range of services in Columbus , perfect for your building or even your house.

TPO commercial

Remplacement, entretien et réparation de toitures commerciales. Un service exceptionnel avec des garanties durables.

TPO résidentiel

Installation de membranes blanches TPO et élastomère sur les maisons. Le meilleur composant résidentiel.

Gouttières

Installation de gouttières, Soffite et Façade en aluminium. Service à la clientèle à long terme. Garantie du service le plus rapide.

Réparations

Réparation de toiture, rapide et fiable avec garanties. Nous offrons une variété de solutions de réparation. Soumission gratuite.

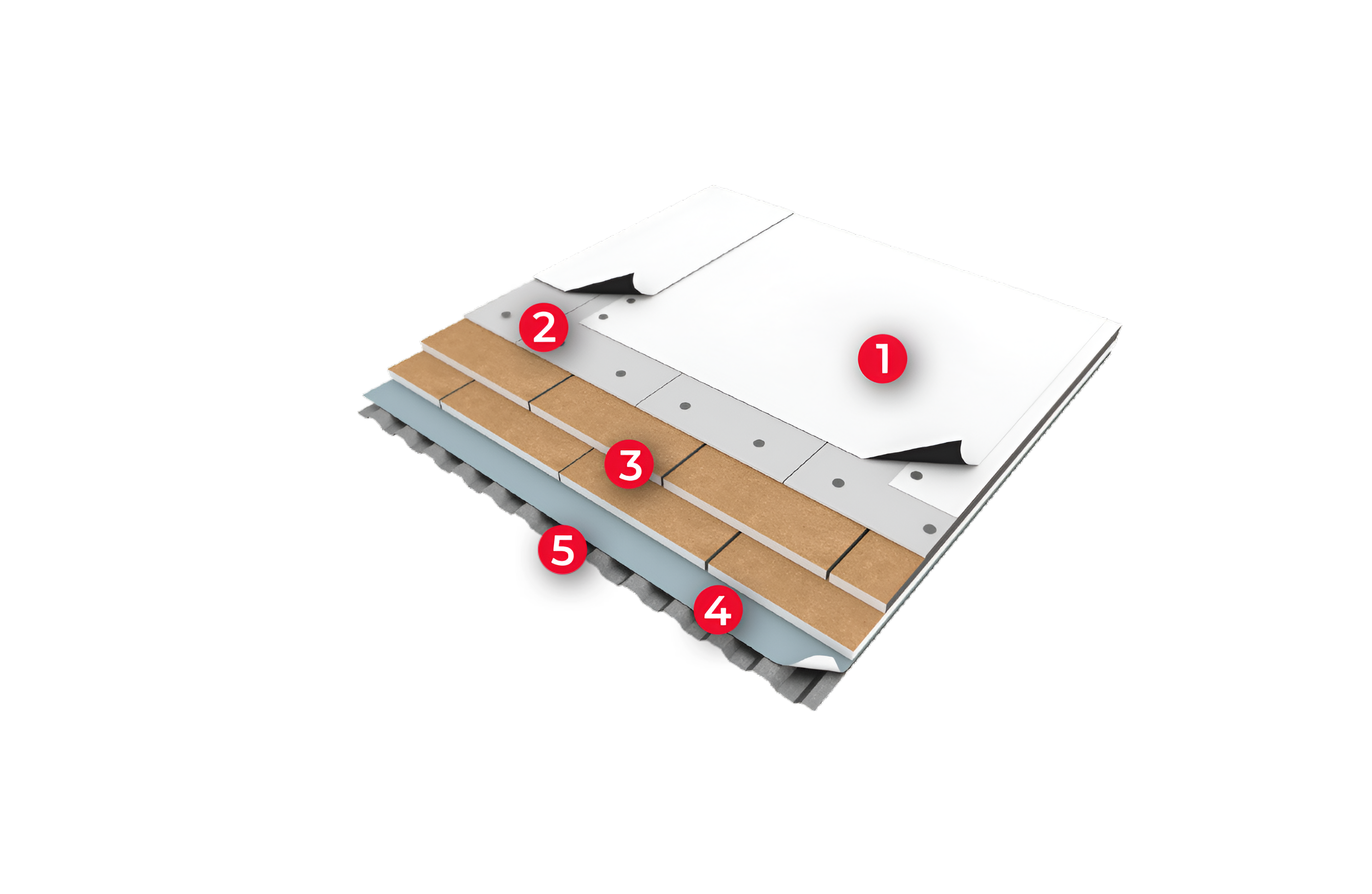

QU'EST-CE QUE LE TPO ?

Le TPO est une membrane de toiture monocouche fabriquée à partir de polypropylène et de caoutchouc éthylène-propylène, souvent renforcée par du polyester ou de la fibre de verre. Connu pour sa durabilité, sa flexibilité et sa résistance aux UV, le TPO est également économe en énergie grâce à ses propriétés réfléchissantes. Il est rentable, facile à installer et peut durer de 20 à 30 ans s'il est correctement entretenu. Le TPO est utilisé pour les toitures commerciales et industrielles, et convient aux toits plats et à faible pente. Des inspections et un entretien réguliers garantissent sa longévité, ce qui fait du TPO un choix populaire pour ses performances et sa nature respectueuse de l'environnement.

L'adhésif de liaison est essentiel pour l'installation de la membrane TPO, en particulier dans les systèmes à adhérence totale. Cet adhésif, généralement une solution à base de solvant ou d'eau, assure une liaison solide entre la membrane TPO et le substrat de la toiture. Il offre une excellente adhérence, améliorant ainsi les performances et la longévité de la membrane. Appliqué à l'aide d'un rouleau ou d'un pulvérisateur, il crée une fixation uniforme et sûre. L'adhésif de liaison est préféré pour sa capacité à supporter les variations de température, à résister à l'humidité et à conserver sa flexibilité, ce qui permet à la membrane TPO de rester intacte et efficace face aux facteurs environnementaux. Des contrôles et un entretien réguliers garantissent l'efficacité à long terme de l'adhésif.

Les fixations et les plaques sont essentielles pour l'installation de la membrane TPO dans les systèmes à fixation mécanique. Ces composants fixent la membrane TPO au support de couverture, assurant ainsi une fixation et une stabilité solides. Les fixations, généralement des vis ou des clous, et les plaques, généralement en métal ou en plastique, sont placées stratégiquement le long des joints de la membrane et des zones de champ. Cette méthode permet à la membrane de résister au soulèvement dû au vent et à d'autres contraintes environnementales. Les fixations et les plaques sont durables, faciles à installer et flexibles, ce qui en fait un choix fiable pour maintenir l'intégrité et les performances de la membrane TPO au fil du temps. Des inspections régulières garantissent l'efficacité à long terme.

Le système d'isolation est vital pour l'installation de la membrane TPO, car il améliore l'efficacité énergétique et les performances thermiques. Les matériaux d'isolation courants comprennent le polyisocyanurate (ISO), le polystyrène expansé (EPS) et le polystyrène extrudé (XPS). Ces matériaux constituent une base stable pour la membrane TPO, améliorant ainsi la valeur R de la toiture et l'efficacité énergétique globale. Une installation correcte implique de fixer les panneaux d'isolation à l'aide de fixations ou d'adhésifs avant d'appliquer la membrane TPO. Un système d'isolation bien installé réduit les pertes de chaleur, diminue les coûts énergétiques et renforce la durabilité et les performances de la membrane TPO, garantissant ainsi une solution de toiture durable et efficace. Des contrôles d'entretien réguliers permettent de maintenir l'efficacité de l'isolation.

La plate-forme de toit est la fondation structurelle située sous la membrane TPO, qui assure le soutien et la stabilité de l'ensemble du système de couverture. Les matériaux couramment utilisés pour les terrasses de toit sont le contreplaqué, les panneaux à copeaux orientés (OSB), le métal et le béton. Un support de toit solide et correctement installé est essentiel à la réussite de l'application de la membrane TPO, car il garantit une surface lisse et uniforme qui favorise l'adhérence et minimise le risque de perforations ou de dommages. La terrasse doit être propre, sèche et exempte de débris avant l'installation de la membrane TPO. Correctement entretenu, il améliore la durabilité et les performances du système de toiture TPO. Des inspections régulières garantissent l'intégrité et la longévité de la terrasse.

Derniers travaux

Journal

Les fondements

Fondée en 2009, nous nous concentrons sur la réparation de toitures, nous nous appuyons sur une grande expérience familiale et des produits de qualité pour vous offrir la tranquillité d'esprit. Actif dans le domaine depuis plus de 20 ans, son propriétaire, Francis Chevalier, met à profit les leçons apprises de son père et de son grand-père pour offrir à ses clients, tant résidentiels que commerciaux, un service rapide et de qualité.

- 857 Chem. Rhéaume

- (514) 953-0983

- [email protected]